Since the late Eighties, Bombay Belting ,has been committed to the development of World Class, Sidewall Conveyor Belts, and our products are now in use in practically all the Continents. We have been pioneers, and instrumental in popularizing this revolutionary technology, in India and overseas. We regularly produce sidewall belts upto 1800mm width.

1. |

Advantages of Sidewall Belts |

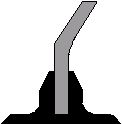

No Transfer Points

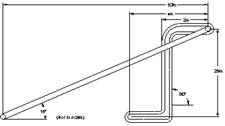

Right from the feed hopper to the discharge point, the belt is capable of turning through any angle up to a vertical line and back to horizontal. This eliminates the need for multi drives and prevents product degradation and spillage at transfer points. |

|

|

| |

|

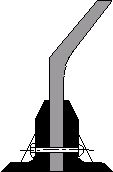

Practically Zero Spillage

Once the material is loaded onto the belt it is efficiently contained between the sidewalls and is prevented by the cross cleat from falling back. As the belt travels along the conveying line it retains the load within its own ‘side skirts’, eliminating spillage, but more importantly, as the sidewalls actually form part of the belt there is none of the wear normally associated with side skirts. The smooth transition when changing angle also ensures the material remains within the belt’s effective carrying area. |

Space Saving

In areas where land is at a premium, i.e. dockside, or within existing plant where space is a problem, SIDEWALL CONVEYOR BELTS provides the ideal solution. With the ability to convey material at angles up to 90 deg. the required ground space is minimal. |

|

|

| |

| |

|

Minimum Maintenance - Long Belt

In cost comparisons between mechanical elevators and SIDEWALL BELT systems it has been proven that the SIDEWALL BELT has considerable advantages. The belt itself requires no maintenance and the reduced number of moving parts plus simple conveyor construction virtually eliminates costly downtime. |

| |

|

Wide Range of Materials can be Handled

With the extensive range of belt sizes available, the SIDEWALL CONVEYOR BELT is capable of handling almost all materials: large lumps, free flowing, delicate or fragile substances, highly abrasive material, light weight or heavy loads. Our application engineers have the experience and a thorough working knowledge to specify the system to suit your needs. |

| |

|

Low Power Requirement, Quiet Smooth Running

A clear advantage of using an SIDEWALL CONVEYOR BELT system is the low power required to move the loaded belt. Because the system can elevate at steep angles (up to 90 deg.), centre distances tend to be small and even in high lift applications power required to elevate is considerably less than in other systems. As the belt is running on rotating idlers, the low resistance results in a quiet system, an advantage when operating in close proximity to personnel. Where environmental factors need to be considered, the system can be totally enclosed. |

| |

|

2. |

Selecting the Base Belt |

|

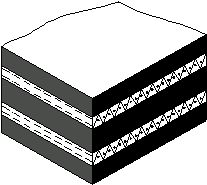

Type ‘XE’

This belt incorporates the cross-stabilising ply in the tensioning ply, mainly used for medium duty applications. |

|

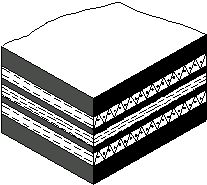

Type ‘XE+2’

The cross-stabilising ply and tensioning plies are separate, in this case the belt has 2 cross-stabilising plies, application areas are medium to heavy. |

|

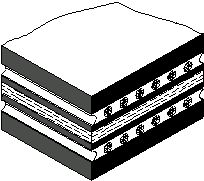

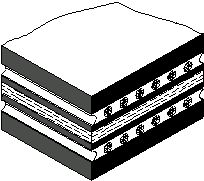

Type ‘XE-SC+2’

This belt incorporates textile tensioning plies with Steelcord cross-stabilising members. The high lateral stiffness means the belt can be used in application areas where rigidity is an important factor, i.e., high lift heights and wide belts. |

|

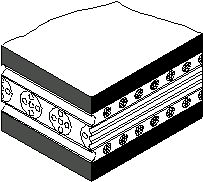

Type ‘XST-SC’

This belt incorporates Steelcord tensioning with Steelcord cross-stabilising members. High tensile strengths can be achieved making the belt ideal for high vertical lift applications. |

3. |

Minimum Pulley Diameters Required |

| Base Belt Type |

Strength (N/mm) |

Cover Thickness (mm) |

Weight

(kg/m2) |

Min Pulley

Diameter (mm) |

Type XE |

250/2 |

2:2 |

9.40 |

200 |

| 400/3 |

4:2 |

13.50 |

315 |

| 500/3 |

4:2 |

13.75 |

400 |

| 630/4 |

4:2 |

15.20 |

500 |

| 800/3 |

4:2 |

16.85 |

630 |

Type XE+2 |

400/3+2 |

4:2 |

12.10 |

315 |

| 500/3+2 |

4:2 |

12.60 |

400 |

| 630/4+2 |

4:2 |

14.40 |

500 |

| 800/5+2 |

4:2 |

16.10 |

630 |

| 1000/5+2 |

4:2 |

17.80 |

800 |

Type XE-SC+2 |

315/2+2 |

4:2 |

13.70 |

315 |

| 400/3+2 |

4:2 |

14.50 |

315 |

| 500/3+2 |

4:2 |

15.20 |

400 |

| 630/4+2 |

4:2 |

16.70 |

500 |

| 800/5+2 |

4:2 |

18.00 |

630 |

| 1000/5+2 |

4:2 |

19.50 |

800 |

| 1250/5+2 |

4:2 |

21.40 |

1000 |

Type XST-SC** |

1600 |

8:8 |

Please

Enquire |

1250 |

| 2000 |

8:8 |

1250 |

| 2500 |

8:8 |

1400 |

| 3150 |

8:8 |

1400 |

| 3500 |

8:8 |

1600 |

| 4500 |

8:8 |

1600 |

Belt Composition:

X = Cross-Stabilised construction.

E = Polyester Tension Plies

+2 = Number of Separate Cross-Stabilising Plies

SC = Steel Cord Cross-Stabilised

XST-SC = Steel Cord **Belt weight will be decided by the final belt design which is dependant on the application.

All S-Wall Cleats have been specifically designed to give optimum performance.

The above are standard heights, non-standard are available, please enquire.

The sidewalls & cleats can be screw reinforced for batter fastening, especially for sidewalls 160mm and above.

| 5. |

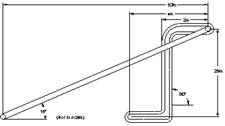

Selecting the Sidewall |

|

The Sidewall design ensures maximum flexing without fatigue, the profile has excellent vertical stability for load retention and return side support. The design allows for high compression to ensure smooth inner deflection around small radii. Another important design feature is that the Sidewalls can be pressed from both sides when mounting, this offers much higher bond strengths and security.

|

|